User Case Study:

Vibration Control of a Warehousing Cable Robot

Challenge

When designing robotics for high-speed applications over large workspaces, motion and vibrations become increasingly difficult to control accurately. As part of the High-Speed Robotics Lab at the University of Waterloo, Dr. Hamed Jamshidifar researches technologies that can aid in the development of new robotics technologies. In a recent project, Dr. Jamshidifar needed new techniques to accurately control the motion of a warehousing cable robot. The modeling techniques he required needed to account for the complex dynamics of the cable systems found in such a robotic system.

Solution

Dr. Jamshidifar used MapleSim, the modeling and simulation tool from Maplesoft, to develop a dynamic model of the warehousing cable robot. By using the dedicated Ropes and Pulleys library within MapleSim, he was able to construct a model that could accurately reflect the motion of the robot and its undesired vibrations. With a sufficiently detailed model in MapleSim, Dr. Jamshidifar could develop and test control strategies to control the vibrations and oscillations that occur during the robot’s movements and interaction with its environment.

Result

By using the model developed in MapleSim, Dr. Jamshidifar successfully demonstrated a simulation-based solution to controlling the vibrations of the robot. The model was created based on a small-scale robot prototype to validate accuracy, and simulations showed the presence of unwanted vibrations. These vibrations were significantly reduced with control strategies implemented in MapleSim. Dr. Jamshidifar will continue using MapleSim models to control and minimize vibrations as these robots are brought to future commercial applications.

In the fields of industrial automation and robotics design, engineering challenges present themselves at all stages of development. Machines are often intended to run as fast as possible, since speed is one of the key factors in the efficiency of an industrial environment. The increasing speed of these machines, however, results in new and complex problems to solve. When running machines at high speeds, changes in both direction and speed can cause significant forces on machine components. Without the proper control strategies for high-speed machines, engineers risk damaging machine components, jeopardizing the safety of both the machine and any nearby operators.

As part of the High-Speed Robotics Lab at the University of Waterloo, Dr. Hamed Jamshidifar researches technologies that can aid in the development of new robotics technologies. He uses modeling and simulation as a key strategy to better understand the dynamics of high-speed robotics. In a recent project, he was studying the dynamics of a high-speed warehousing cable robot. These robots are intended for use in warehouses, where products need to be moved over large workspaces at high speeds. By taking advantage of cable systems to move the robot between locations, Dr. Jamshidifar’s design can provide faster operation than traditional warehousing robots.

To achieve the high speeds possible with the new robot design, motion and vibration control would be a crucial part of the design process. Without high-fidelity machine controllers, the cable-driven robot would be easily susceptible to unwanted vibrations and other unintended motion that would impede performance and risk damaging the actuating motors and surrounding environment. Dr. Jamshidifar chose MapleSim, the modeling and simulation tool from Maplesoft, as a key technology to understand the robot’s dynamics and develop control systems that could accurately minimize and control vibrations. While other modeling and simulation tools exist, MapleSim offers a dedicated Ropes and Pulleys Library which allowed him to easily incorporate cable dynamics in his simulations.

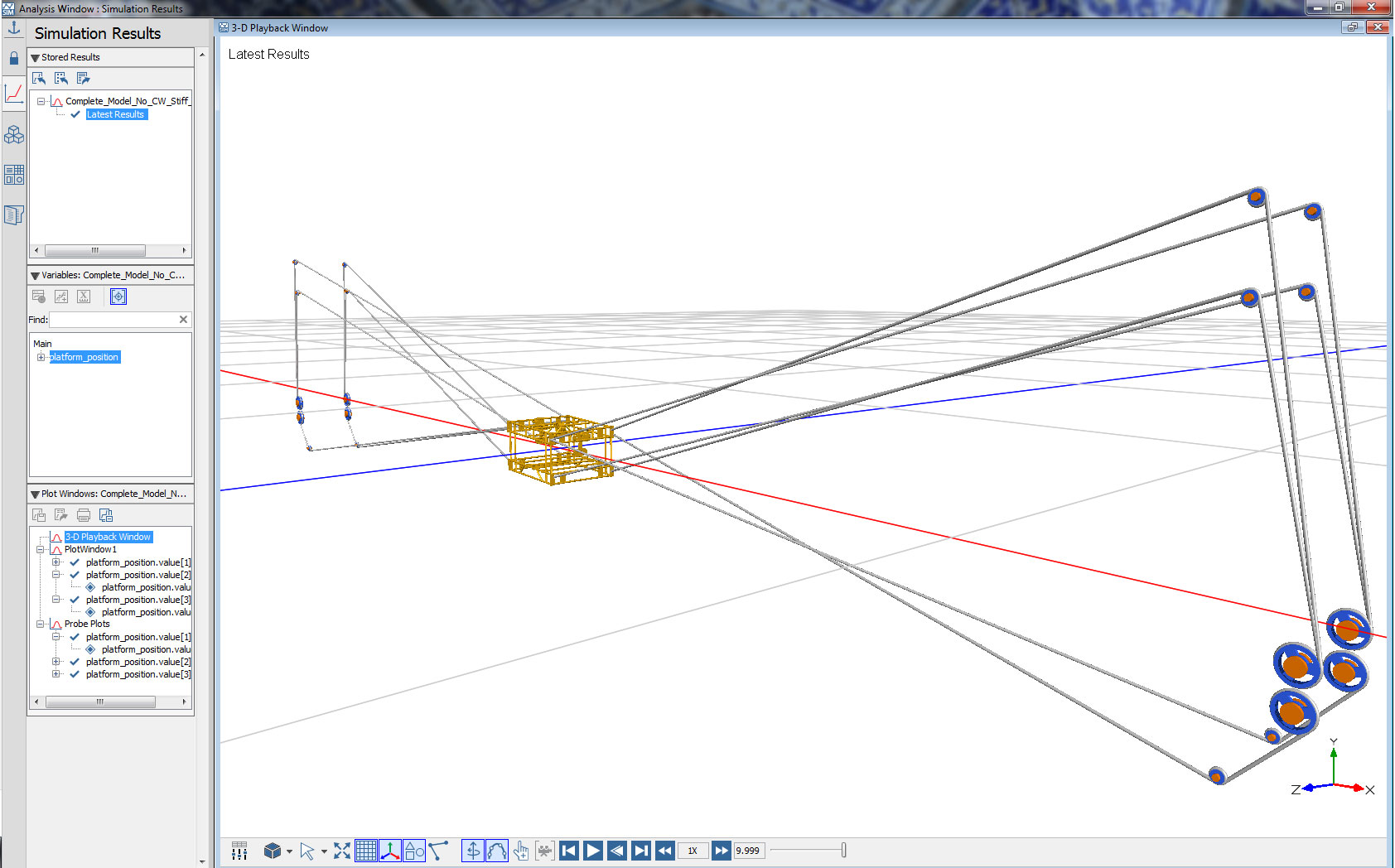

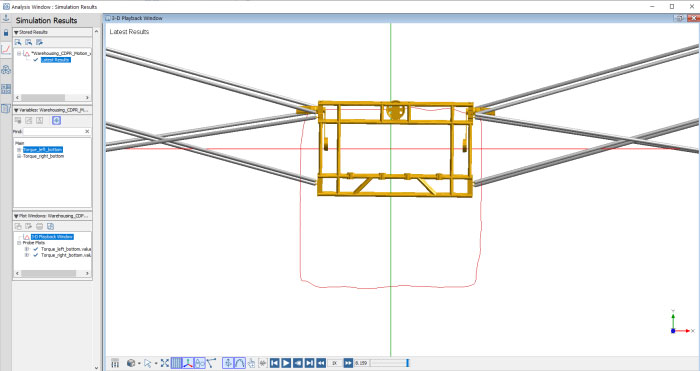

Figure 1: A 3-D visualization of Dr. Jamshidifar's model in MapleSim.

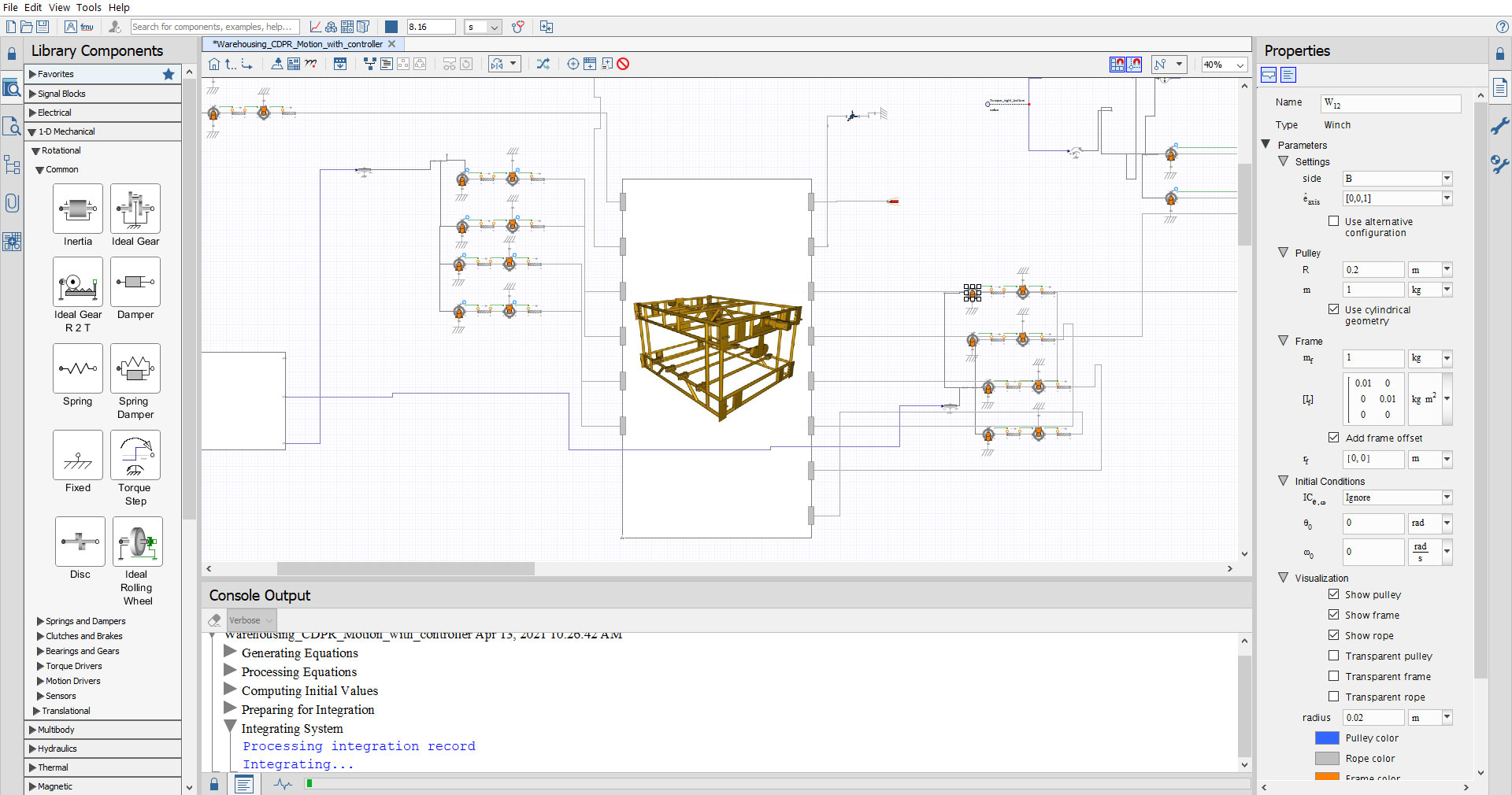

To create the robot model in MapleSim, Dr. Jamshidifar imported his pre-existing CAD model of the robot’s moving platform. By importing his CAD model, he could automatically import the platform’s geometries, mass and inertia information, and the 3-D model information for visualization purposes. The model was then completed by connecting standard MapleSim components, including pulleys, winches, and cables. For the purposes of testing the model, the winches were actuated by simplified forces to simulate the movement of the robot along a rectangular motion path.

Figure 2: The warehousing cable robot model in MapleSim, showing the central platform connected to cable and winch systems. Winch parameters are seen on the right side of the MapleSim workspace.

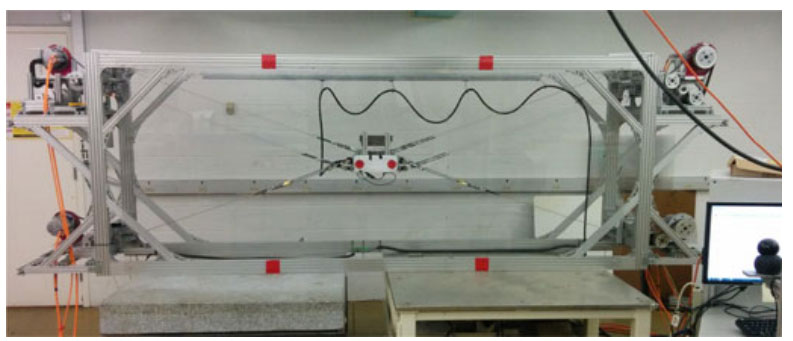

To validate the model accuracy, simulation results were compared against a small-scale physical prototype that was previously constructed. This would ensure that the basic dynamics of the MapleSim model were aligned with the expected results during operation.

Figure 3: A small-scale physical prototype of the cable-driven warehousing robot.

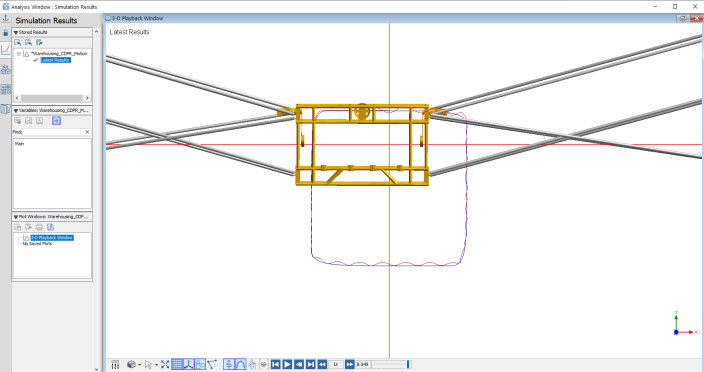

The simulation results for the robot could be visualized in MapleSim using a 3-D representation of the pulley systems in combination with the previously imported CAD. The initial simulation results show the problematic vibrations of the central platform. Without proper motion control, these vibrations would limit both the speed and safety of the robot’s operation. The MapleSim model would be used to test and validate various control strategies to minimize these vibrations, while still allowing for the maximum safe operation speeds.

The second set of simulation results show the results of an elementary control strategy to minimize vibrations. The motion was compared against the previous, non-controlled results, showing the amount of vibration that was eliminated during the motion profile. The simulation results pictured are still only the product of preliminary attempts to reduce vibrations – Dr. Jamshidifar intends to develop control strategies and algorithms that will further reduce the vibrations in all operating conditions.

Figure 4: Visual results for the planar vibration of the warehousing robot model. The motion path is traced, and can be seen to oscillate without motion controllers (left), whereas the motion controllers are shown to stabilize the platform's movement (right).

Dr. Jamshidifar was able to demonstrate that the unwanted vibrations in his cable-driven warehousing robot could be minimized with the correct control strategies. By continuing to use MapleSim for his research and development, he will be able to minimize the chance of issues when developing physical prototypes, having already eliminated various issues in the MapleSim model. As he continues to develop the robot model, Dr. Jamshidifar plans to use his MapleSim models to accurately develop control strategies and algorithms that can bring faster, better robots to market for warehousing applications. The team has currently developed a full-scale prototype, with plans to bring the robot to commercial markets in the future.

Figure 5: A full-scale prototype of the warehousing cable robot.

Contact Maplesoft to learn how MapleSim can help with your projects

Contact Maplesoft to learn how MapleSim can help with your projects

Products

Industry/Application Area